Illumination Systems

Illumination Systems for Microscope Spectroscopy

Illumination systems for microscope spectroscopy should cover the range between 195 nm and 2200 nm. This is crucial for detailed analyses, for example on fibers or layer thicknesses. For this purpose A. S. & Co. provides special illumination concepts and optimizes the generally available microscopes for the DUV-NIR range through appropriate modifications.

Spectroscopy in visible light

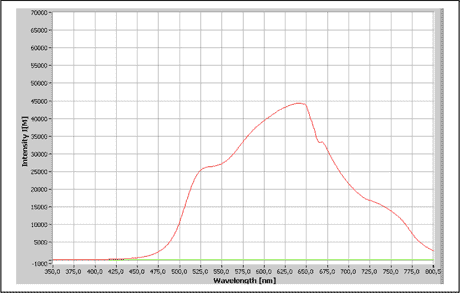

The standard working range for spectroscopy in the visible light from 350 to 700 nm can be covered in the simplest case with lamps of the microscope provider. These are directly coupled 100W halogen lamps with the advantage of high luminance, thus enabling in addition to the usual bright field microscopy also spectroscopy in polarized light and dark-field spectroscopy. Specifically the dark-field spectroscopy allows the measurement of nanoparticles and size distributions under optical microscopic conditions, for which preparation methods are much easier in comparison to electron microscopy.

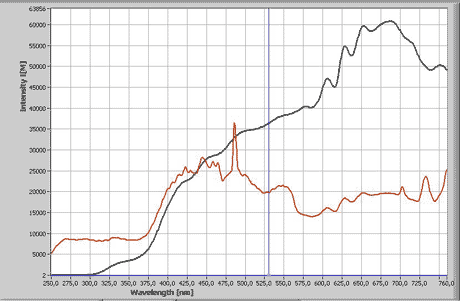

Typical spectral distribution in a modern microscope, which is equipped with filters for blocking both the NIR and the UV range.

A disadvantage of these lamps is their high current intensity, which can lead to voltage fluctuations and therefore to intensity oscillations. Even though these are "only" in the range of approximately one percent, they nonetheless have a noticeable effect on the quality of the spectra and require signal averaging by the SpectraVision software.

Helpful is a PC-controlled highly stabilized power supply as an alternative for the built-in version in the microscope. It provides a sufficiently stable intensity, and reduces the time-consuming spectra averaging.

External power supply for highstability control of microscope light sources

© A.S. & Co. GmbH

The better alternative is a fiber-coupled halogen light source designed specifically for the requirements of spectroscopy. It has a factory-optimized highly stabilized power supply and can often be operated in combination with a spectrometer module in the same rack.

Example of a fiber-coupled halogen lamp CLH as plug-in module together with a spectrometer cassette type MCS in a shared 19" rack

CHL characteristics:

- 12V, 20W

- 340-2000 nm, at ca. 3000K, Option:

electronic shutter 1Hz - Convex lenses for fibre optic

Recently, the trend is to replace halogen by LED illumination. General advantages compared to halogen are:

- long life

- high stability in the illumination intensity

- constant color temperature at different brightnesses

- low power consumption

- cold light, so mostly without fan (completely silent)

For spectroscopy, which requires a constant light emission over the entire range, there are limits in this regard. For with the white light LED, certain wavelengths are very low, thus showing gaps in the spectrum. To obtain a well-balanced spectrum of white light, several different colored LEDs may be combined. For this purpose solutions of different manufacturers are available, which we integrate into our concepts. The LED illumination can be mounted directly or fiber coupled to the microscope.

Extension for Near Infra Red (NIR)

Because halogen lamps emit a large portion of their energy as Near Infrared, their emission is usually quite sufficient for the NIR spectroscopy. However, it is important to ensure that the microscope used is designed for the NIR range. Because most devices have built-in heat filter and optical elements that suppress specifically the NIR range. To avoid damage to the microscope and its optical components by heat radiation, these modules cannot be removed without being replaced, but are to be exchanged with NIR-suitable variants.

A.S. & Co modifies the standard microscopes and optimizes them for the NIR range with switchable protection filters that open the range of the device-damaging irradiation only for the millisecond measurement process.

Extension for Deep UV

Since the introduction of infinity corrected optics standard optical microscopes are designed with a transmission window between 310 nm and near infrared (NIR). Measurements in spectroscopy, however, can require ranges starting from 230 nm. For the long-term stability of the anti-reflection coatings of the optical components, it is necessary to incorporate appropriate precautions against their fading due to strong UV irradiation. In addition, of course, health and safety regulations have to be considered, which are mandatory for dealing with UV light.

A. S. & Co. modifies the standard microscopes and optimizes them for the UV application range with

- external assist lights that complement the measurement light and are used in place of this for the centering of fiber-coupled light sources so that UV light is emitted only for the short period of measurement.

- fiber collimators that can compensate the longitudinal chromatic aberration of UV

- exchange of coated components through full glass elements. Although these are designed technologically complex, they provide anti-reflective, high-contrast-enhancing results without coatings

- own DUV-NIR blocking filters with reticle pattern as eye protection in the eyepiece

For use in the deep UV microscopy A.S. & Co. integrated further modifications:

- In the microscope basic stand all optical lenses and mirrors in transmitted light are replaced by elements with UV-suited properties, and

- Inside the phototube the prisms and the tube lenses are adapted to the requirements of the DUV-NIR microscopy

These modifications have significant impact on the sensitivity and the data quality (see display of the spectra)

Impact of the modifications on the beam guidance

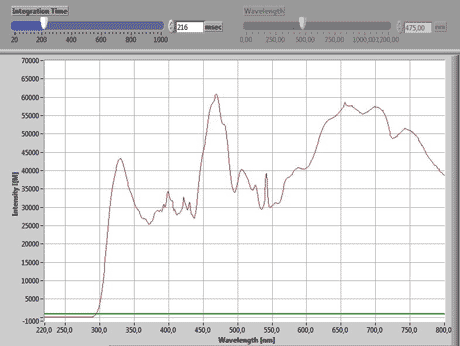

Above:

spectrum of microscope illumination before the modifi cations. Light transmission starts at 300 nm, measuring time 216 msec.

© A.S. & Co. GmbH

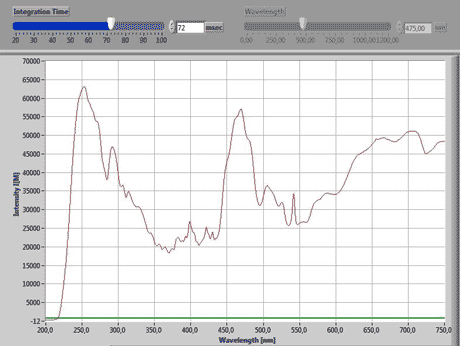

Below:

spectrum after modification. Two effects become evident:

- start already at 200 nm

- short measuring time of 72 msec. Overall, the measuring time shortens to 50–250 msec. Without these modifi cations the recording time is three times the power of ten longer, up to 5 sec, for this dynamic range.

© A.S. & Co. GmbH

DUV radiation and lens damage

According to the literature the combination of directly irradiating UV lamps leads to extreme transmission problems at DUV suitable lenses already after a short application period, although the same objective class has been used in the microscope photometry with monochromators as standard for decades without any problems. Looking at the handling of older systems, these problems can be assigned. Microscope photometers from the type MPM and MPV utilize for the adjustment of the sample and the selection of the measuring spot light of halogen lamps or UV sources, the wavelengths of which have been limited by the monochromator preferentially to green light. The device damaging UV light is entering the microscope only during the measurement and is irradiating the lenses only during the detection period of the short-wavelength segment. Experience shows that this approach was able to maintain the microscope photometer for more than 20 years in fully functional condition, so that they did not need to be replaced due to optical defects.

In contrast, modern systems make use of the entire spectrum not only during the measuring period, but also for the sample positioning. In addition, with regard to the excitation pinhole often further technological compromises are made, so that at any time the full lighting power is entering the microscope and thus is irradiating its optical parts.

A. S. & Co.-specific illumination modules for DUV spectroscopy, for increasing system sensitivity and for reducing the DUV-NIR illumination intensity are currently unsurpassed in dealing with this issue.

Illumination for Deep UV Spectroscopy

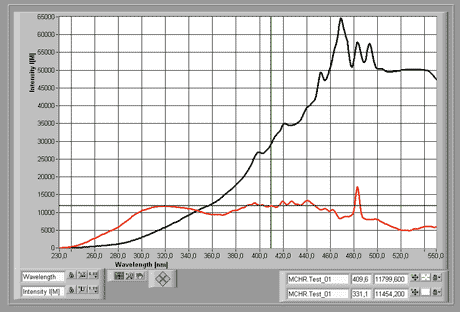

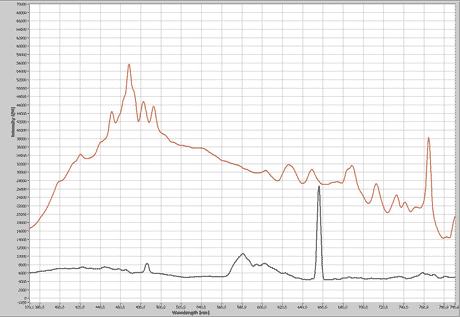

The emission spectrum of a xenon lamp shown below represents what has been for decades the standard illumination used in UV spectrometers. The problem with this spectrum lies in the range under 300 nm, as in comparison to its maximum in the blue-violet, the energy yield here is only around 5%. This leads to high noise levels and totally unusable results for wavelengths under 280 nm.

The excitation spectrum from a deuterium lamp can help here, as it produces its best energy yield starting from 220 nm. Unfortunately these lamps can only be used up to about 550 nm, as in longer wavelengths they are much weaker, and further, in the red range they show undesirable intensity peaks, whose level significantly reduces the spectrometers dynamic range.

Comparison of the emission spectra of a Xenon lamp (black) with that of a deuterium source (red)

© A.S. & Co. GmbH

The solution lies in a deuterium-halogen combination. For this, two possibilities are available.

Deuterium-Halogen Combination on a Single Optical Bank

A deuterium and a halogen lamp, with separate power supplies but a common optical system, are combined in a single housing. The unwanted side-effects of the deuterium source are filtered out, and both spectra can be combined into a shared optical-fiber guide.

This lamp combination provides a compact, economical solution for supplying the total excitation spectra. It can be triggered as a combination spectrum via the shared shutter. The utilization of the halogen lamp for observing the sample and adjusting the beam path, however, is only possible in an extra procedure completely separated from the measurement. This is necessary to prevent damage from the sample and the microscope.

In order to be able to correct for example the measurement aperture during a measurement, SpectraVision provides a pilot light. It is integrated in the collimation optic and switched simultaneously with the excitation illumination. Thus, the device-damaging Deep UV illumination can remain switched off during the positioning and adjustment procedure.

that via a y-lightguide is switched on simultaneously with the excitation illumination, so that the is switched off during the setting up and centering procedures

| Characteristics of a deuterium-halogen combination illumination | |

|---|---|

Deuterium module:

| Halogen module:

|

Independently operating deuterium and halogen lamps

This setup represents the optimum combination. Each has its own highly-stabilized power supply and can be individually integrated into the measurement and observation processes

Furthermore, the advantage with separate lamps is that by use of suitable filters, the deuterium lamp is only activated above 220 nm for microscopic applications, so that the lightguide used can be operated in a solarisation-resistent manner. The measurement setup therefore remains stable in the medium-term. The not required long wavelengths are naturally also corrected.

Concerning the brighter halogen lamp, its intensity can be adjusted via the installation of individually-matched grey filters to complement the performance of the deuterium lamp. This has the effect that the combination of both lamps can significantly improve the dynamic range of the excitation spectrum and also allows the detection of the smallest variations in brightness.

Example of optimization of the dynamic range (red) through individual matching of the separate deuterium and halogen illumination

© A.S. & Co. GmbH

| Characteristics of the separately-operated deuterium and halogen lamps | |

|---|---|

CLH characteristics:

| CLD characteristics:

|

All lamps from A. S. & Co. are coordinated through the SpectraVision Basic Software. This integrates the microscope's functions and provides for

- fully automated switching of lamps and microscope shutters

- swivelling-in of attenuation filters, so that a change in intensity between the measurement illumination of 3200K and the observation illumination can be made without voltage change.

- an automatic dark current correction

Compensation of the lower light intensity of the deuterium halogen combination

Compared to a conventional Xenon UV lamp, the deuterium halogen combination has a much weaker light intensity. In order to be still able to use the described advantages of this combination, the increase in system sensitivity together with the reduction of DUV-NIR illumination by AS & Co. gains particular importance.

Comparison of the irradiation intensity between a XBO 75 (red) and a deuterium halogen combination (black)

© A.S. & Co. GmbH

Increase in System Sensitivity

Optimization of the Beam Guidance

Specific, by A. S. & Co. developed modules for optimization of the beam guidance lead to a significant increase in the system’s sensitivity compared to standard microscopes that are used in the conventional systems available on the market so far:

- mono fiber-coupled spectrometers provide a circa 30% higher signal transmission from the microscope to the sensor compared to the conventional y-fiber.

- an integrated light source inside the fiber collimator allows the direct illumination of the measuring aperture and prevents the loss of light by beam splits in the microscope.

- modified spectro phototube: The standard phototube was optimized to a higher light throughput. Since all optimizations potentiate, the improved light throughput at the tube has a positive impact on the overall performance and reproducibility. Together with the A. S. & Co. product "Live overlay module" the illumination pinholes and measuring pinholes are reflected direct to the eyepiece. The viewer observes the sample image as well as the aperture, its position, size and sharpness simultaneously live.

Sensor with highest possible Sensitivity

Another aid is the use of an extremely sensitive sensor which increases the bright-field DUV transmission. It reduces measurement periods and thus protects both device and sample. A.S. & Co. DUV Microscope Spectrometer Systems are based on a Peltier-cooled CCD array with1024 x 64 pixels, which gives a resolution of 0.8 nm/pixel. There are several features that improve the sensitivity:

- The most important criterion is the pixel size, because the greater the measurement area, the better the sensitivity. In comparison to a usual photo camera size with 2-6 μm spectrometers of A.S. & Co. offer 24 x 24 μm pixels. This is about 15 times larger.

- The array layout also has a vertical dimension of 64 lines. Vertical binning over 50 pixels exceeds the active detection area of more than 28,000 square microns per 0.8 nm resolution. The large detection area resulting in excellent sensitivity makes the sensor an ideal measuring tool for critical fluorescence observations.

- The cooling system improves the noise reduction. The results are distinct curves that can be used for interpretation reducing the need mathematical smoothing or averaging.

- In addition, cooling ensures a constant signal/noise ratio during data recording, because the sensor is always at a constant temperature. It is therefore independent of the laboratory conditions. This is of particular importance as geological measurements from different climate zones are often directly compared on the basis of applicable worldwide standards.

Reduction of DUV-NIR Illumination Intensity

Specific components of A. S. & Co. provide options for reducing the light intensity and the amount of damaging light.

Use of DUV Field Diaphragm

Apertures on the excitation side are able to perform this task, as this kind of microscope spectroscopy presented here usually uses only a small narrowly defined, rectangular or circular measuring spot. Thus it seems likely to exclude the area not required by appropriate aperture. This leads not only to a significant increase in contrast through decrease of scattered light, but also to a significant decrease of UV exposure.

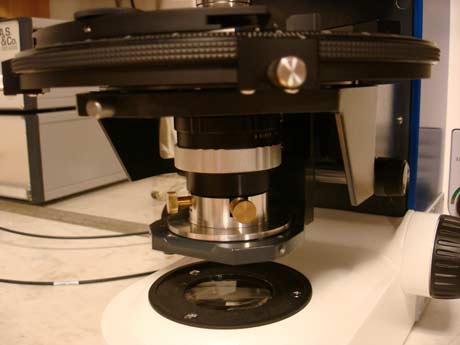

DUV illumination module with integrated measuring aperture and auxiliary illumination for aperture adjustment. The illumination for the spectroscopic measurement of the sample is done via fiber-coupled external lamps, while the synchronization is performed by the A.S. & Co. controller. The aperture is available in a rectangular shape. The length of each side can be adjusted individually by four adjustment screws. The fiber can be aligned to the optical axis of the system by a separate x/y positioning.

© A.S. & Co. GmbH

Consideration of the illumination principle of August Koehler

Combining the above mentioned DUV field diaphragm additionally with a Deep-UV-suited condenser concept, a UV illumination is generated with best possible focus of its energy to the measuring area. The efficiency gain together with the replacement of the classical illumination beam path by UV- compatible modules results in a further reduction of the irradiation intensity. Also the color fringes caused by diffraction patterns at the aperture blades recede into the background and are negligible compared with the measuring signal.

Our Koehler condenser with high precision fine drive was developed to align an extremely small pinhole under high magnification.

DUV Koehler condenser with high precision fine drive

© A.S. & Co. GmbH

External field stop; when using a total magnification of 1600x an area of < 2x2 μm can be illuminated.

© A.S. & Co. GmbH

Working with such a small aperture offers advantages:

- Undesired high energy, which destroys lenses and coatings inside the microscope, is reduced to a minimum.

- The excitation light is focused precisely to the sample area only.

- Full exposition with the best possible numerical aperture.

- The exposition time of the sample remains in the millisecond range.

- Thus, the sample will not get damaged by heat or high energetic light.

- These properties avoid costs for extra maintenance and replacement of optical parts and lenses

XBO Illumination for Microscopy

The high-pressure xenon lamp is, in addition to the halogen lamp,one of the oldest light sources for microscope spectroscopy. Similar to the halogen illumination most of the tasks can be solved with the microscope's original equipment lamps. Practicle experience over decades has shown that in the performance comparison the 75W XBO lamp has the most effective radiating characteristics, so that the best results are achieved with this light source. The quality concerning the emission characteristics and the life expectancy is determined through the stability of the arc and its power supply as well as through the selection of the glass tube. The typical lamp spectrum shown below is characterized by a high intensity with extremely short measuring times.

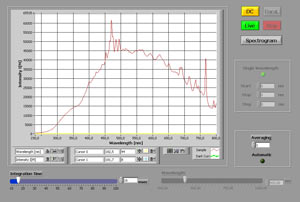

Typical lamp spectrum of XBO illumination in a microscopic beam path

© A.S. & Co. GmbH

At the same time quite weak light yield in the Deep UV is to address. It can be noted that XBO lamps are justified, when due to the combination with monochromators an illumination has to be provided with highly specific and extremely accurate wavelength, which requires a high irradiation energy.

Monochromators in Combination with Xenon Illumination

For this application, compact solutions from a wide variety of providers are available, which use either the fast galvanometer principle or the much more precise stepper motor drives for positioning the monochromator grid. Also increasingly more versions with Acousto Optical Tunable Filter (AOTF) are available. These are passing the, although significantly more limited, wavelenght range at infinitesimally short switching times. The systems have in common that in combination with cameras for fluorescence measurements or in combination with spectrometers and photomultipliers they enable densitometry and colorimetry in the highest resolution range.

A. S. & Co. has integrated various models in SpectraVision, and has combined these with software for two-dimensional analysis and for spectral mapping. On request we will be pleased to explain our concept in more detail.

Modular Double Monochromators in Combination with Xenon Illumination

In general we favour a modular assembly consisting of an external XBO illumination in combination with a separate double monochromator. This monochromatic illumination unit is coupled via a fibre optic connection, either as a full-field illumination for video, or as a spot-illumination for spectroscopy. The advantage of this modular assembly lies in the individual configuration of the separate components. So, for example, through the use of an aspherical quartz collector, the maximum possible intensity of the XBO can be focused on the entrance slit of the double monochromator

The first grid is optimised to

- the wavelength scan range

- the determination of the most effective wavelength

- the location of the desired dispersion effectiveness

- the requisite resolution with the resulting energy balance

The selected wavelength is mapped on a second slit, the dimensions of which determine the half- width, while through the duplication of the assembly the sidelobes and the scattered light are very effectively blocked. A fiber optic connection with cross-section-converter and a centerable collimation optic project the energy on the exit slit in the microscope's target area.

For suppression of scattered light an additional cut-off absorption, cut-on absorption or interference filter can be swiveled into place in the beam path via a motorized filter wheel, and a magnetic interlock is positioned behind the entrance slit to protect the grid from unnecessary UV radiation.

A. S. & Co. tailors these assemblies individually according to the requirements of the customer's applications – as an example, the beam guide for a standard assembly is shown here.

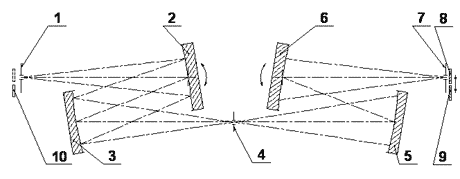

Double monochromator 200-800 nm

Beam principle of a double monochromator with its components

- adjustable entrance slit

- movable spherical imaging mirror

- spherical grid with variable characteristics

- intermediate slit, adjustable for determining the half-width

- spherical grid with variable characteristics

- movable spherical imaging mirror

- adjustable exit slit

- scattered light compensation filter set

Characteristics of a standard monochromator

- Wavelength range: 200-800 nm

- Apertur Ratio: F/3,5

- Resolution with a 2mm entrance slit: 1.5-14 nm

- Scattered light: 10exp-7 at a distance of 20 nm and Lambda = 632.8

- Wavelength reproducibility: 0.5 nm

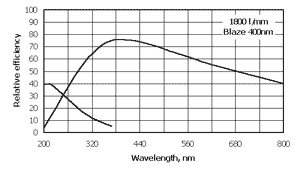

Efficiency curve for a grid with a transmission range from 200-800 nm and an effectiveness optimization (Blaze 99 at 400 nm)

Xenon Illumination as Flash Modules

For applications in the life sciences area as well as in the machine vision area pulsed light sources are often utilized. For this reason A. S. & Co. offers flash modules based on Xenon tubes – they are of modular design and are fitted in their own cases with suitable power supplies, and are coupled to the microscope via fiber optic connections. Similarly to monochromator systems, full image illumination and spot illumination are possible. Positioning of the illumination is achieved by use of our centerable collimators, in which a continuous pilot lamp illumination will aid in positioning, this illumination being either integrated in the collimator, or switched-in via a y-light guide

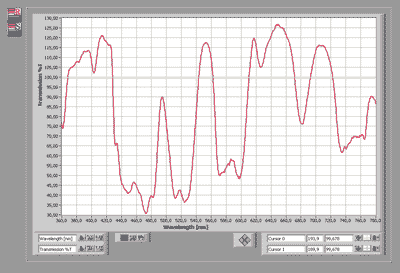

Holmium filter spectrum as example for an XBO flash illumination:

A frequency of 50 flashes as a reference and sample is recorded and averaged. The transmission result is comparable with the quality of established illumination techniques, but the irradiation intensity needed is considerable lower, so that this method is definitely recommended for UV-critical samples.

Xenon Flash Lamp DUV

- 0.4J/flash

- slide-in module: 240-800 nm

- Frequency: 80 flashes/sec

- external trigger

Xenon Flash Lamp UV-VIS

- 0.6J/flash

- slide-in module: 280-800 nm

- Frequency: 30 flashes/sec

- external trigger