Reflected Light Microscope Spectrometer for Paints and Glass

Analysis of pigments and reflected light samples

In reflected light microscopy dark field and polarization measurements are standard methods. For these evaluations only small amounts of light are available. Special components, designed by A. S. & Co., provide an efficient beam guidance thus increasing the sensitivity of the system compared with standard configurations.

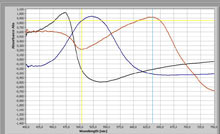

Spectra of pigments from the three main layers of a color negative film

© A.S. & Co. GmbH

Technical Features

- light sources with a special external power supply, with a stability significant above those used by standard commercially available microscopes

- short optical paths with specially adapted components and optical coatings that in the case of NIR measurements, neither exhibit increased absorption nor a degradation of optical characteristics due to thermal exposure.

- easy to use adapters for measurement and illumination with iris apertures or quick and easy switchable fixed apertures in order to minimize over-illumination of the small sample area.

- apertures with integrated illumination to project the aperture image online into the eyepiece when the system is equipped with a reflector revolver and a tube with beam splitter. This provides for more precise alignment of the measuring sample and higher data quality.

- pinhole live overlay module: Sample and pinhole can be overlaid online through the eyepiece to place extremely small structures precisely into the measurement area

- avoiding the loss of light intensity due to chromatic aberration with the use of aplanatic, achromatic optics with long working distance for the condenser and lens.

- cooled CCD sensors with high sensitivity for the display of spectra from light-sensitive dark field measurements

- combined VIS NIR modules based on photo-diode-arrays for improvements in resolution and spectral bandwidth

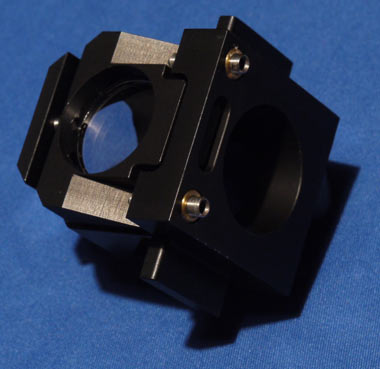

Fiber collimation system with high precision -xyz alignment

- xy-fiber alignment of the collimator

- Adjustment of pinhole size and position

- z-focusing

© A.S. & Co. GmbH

Live Overlay Element imbedded in a P & C module for Carl Zeiss microscopes

© A.S. & Co. GmbH

Specials to improve System Sensitivity

Specific, by A. S. & Co. developed components / configurations cause a marked increase in sensitivity compared with conventional systems on the market:

- Mono fiber-coupled spectrometers provide a significantly higher signal transmission from the microscope to the sensor compared to the conventional y-fiber.

- Collimator integrated light source enables direct pinhole illumination. It replaces the y-fiber and avoids any beam-splitting in order to raise the system’s sensitivity to its maximum.

- Modified A.S. & Co. spectro phototube: standard correction elements for the adaption of TV cameras have been replaced by optical groups, which are optimized for precise representation of pinholes with extremely small diameters. Together with the life overlay module, they represent the pinhole directly in the eyepiece. The viewer observes the sample image as well as the aperture, its position, size and sharpness simultaneously.

Highest Precision through motorized Functions

Analysis of surface structures using optical methods requires a precisely positioned and focused sample on a research grade microscope. For this purpose motorized z-drives are very useful; after a change of the sample the drive returns the new sample fast and reliable to the position in focus. This speeds up the process and makes it more reproducible. In addition motorized x-y stages allow the automated measurement of spectra at defined positions; the spectral profiles allow conclusions about the homogeneity of the sample. The synchronization between spectrometer and microscope along a defined distance enables the measurement of gradients in the refractive index or color changes in the micrometer range.

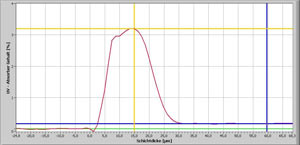

Example of synchronization between the spectrometer and scanning stage: The stage moves automatically over the paint gradient (left) and generates a gradient profile from which the layer thickness can be calculated (right).

© A.S. & Co. GmbH

Further Motorized Microscope Functions simplify the Measurement SpectraVision reflecting microscope spectrometers are available with various comfort levels. In combination with simple routine microscopes only the evaluation of the dark current is automated. When using motorized research microscopes, the SpectraVision software can control the illumination, the use of light-reduction filters and the switch of a prism in phototubes or camera ports. The use of light-reduction filters allows the adaption of the illumination for measurement, without the need to change the intensity of the illumination system itself; this guarantees the most stable and clearly defined intensity at all times. Motorized phototubes allow automated switching between a splitted observation beam path to the eyepiece and the 100% redirection of the light to the sensor, especially for the observation of samples that show weak intensity.

Fast Operation via Online Monitoring Function from a single Window

A fast and reliable check of the illumination and measurement condition is important to get the maximum dynamic range and the highest precision for the measurement. The Autoadjust function in software is a valuable tool for the independent definition of the optimal measurement duration and the evaluation of the best dark current signal. The objective to measure a spectrum is achieved with a few simple steps.

The SpectraVision software automatically stores as Header automatically all information for the identification of device and data, sorts the spectra in ascending order and provides space for individual notes.

© A.S. & Co. GmbH

A first evaluation can be done by a visual comparison of spectra. The evaluation window allows the comparison of the data. Useful tools like averaging of the data and the graphic presentation of their variations assist in the interpretation of the results. Further tools such as addition, subtraction, normalization and derivations are available. If mathematical calculations are preferred, this can be done with scatter analysis. The degree of spectral consonance can be calculated with Euclidean distance function. For further individual evaluations the data can be exported to Microsoft Excel or other analysis programs.

For documentation standard protocol templates as well as variable templates are available, in which the data of the measuring process and their result are entered automatically.